Training Contents

- Scientific fundamentals of eddy current testing

- Characteristics of eddy current

- Equipment design and functions of devices

- Eddy current probes

- Screening testing, measurement of dimensions and film or layer thicknesses

- Eddy current testing of tubes and pipes, bars and wires

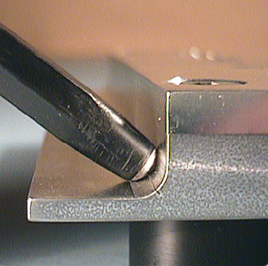

- Flaw detection by means of sensing probes

- Device engineering

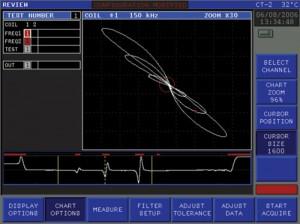

- Evaluation techniques

- Screening inspection and material identity verification

- Eddy current inspection of tubes and pipes, bars and wires

- Eddy current inspection of steam generator tubes

- NDT Lab Reporting

About the course

This inductive method is used to detect flaws on the surface of electrically conductive materials. The training course focus on the fundamentals of the testing method: magnetic induction, a.c. engineering, presentation of impedance levels. The use of general-purpose and specialized equipment will be practised intensively. An overview will be given of applications in the industrial sectors of pressure vessel construction, pipe and tube manufacture and the aeronautical industry. Material identity verification will be dealt with for participants from all industrial sectors.

Moreover, the course focuses on the selection of the inspection parameters and evaluation of eddy current indications for the pressure vessel construction, pipe and tube manufacturing and aeronautical industry sectors. Work will be centred on implementation of standards currently applicable. The possibilities presented by frequency mixing, the inspection of ferromagnetic materials using the stray flux method, and eddy current inspection involving permeability suppression will all be dealt with at depth.